Centuries-Old Watch Industry Embraces 3D Printing

We hear about all sorts of items being made via three-dimensional printing… but watches? Absolutely. In fact, over the past few years, more and more watch brands have been using 3D printing in creating prototypes of watches that are in the research and development stages. It considerably helps to speed up the process.

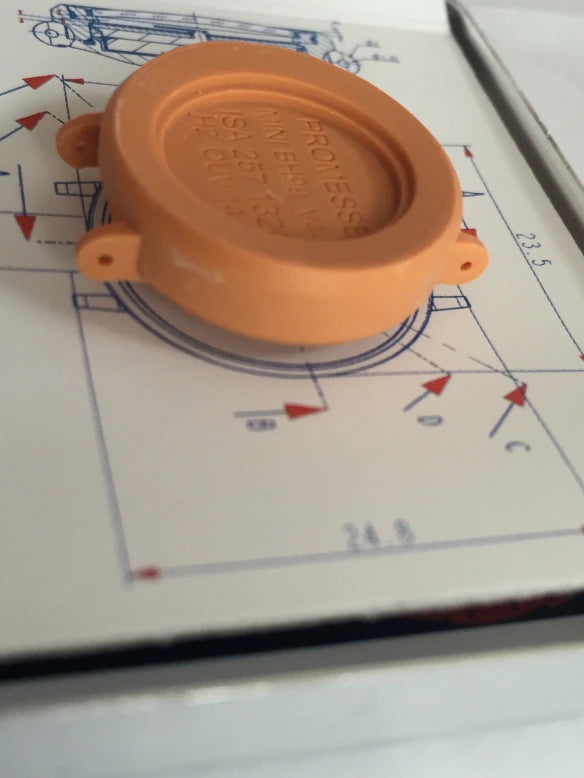

By three-dimensionally printing cases and bracelets, designers and watchmakers can study the ergonomics of the pieces, the sizes, the curves and the fit. In the past, a watch brand would create a mold and then have samples made for them to see, touch and feel. This process would easily take a few weeks each time something would be altered in the prototype. However, three-dimensional printing takes almost no time in comparison.

In a recent survey, more than 60 percent of watch executives said they already use 3D printing for prototypes of cases, dials, bracelets, buckles and crowns. The benefits of moving more quickly also equal a labor and time reduction, which may help influence eventual prices. Additionally, because objects are designed on a computer for 3D printing, it is very precise, giving watch brands an excellent representation of how the piece will turn out when finally made for real.

Thus far, none of the top luxury watch brands are actually making 3D-printed watches, however, several of the finest haute horlogerie companies are secretly investigating new production methods in laboratories and universities. We can’t wait to find out more, and when we do, we will keep you posted.